The 8-Minute Rule for Roof Nuts

Table of ContentsThe Buzz on Roof NutsThe Roof Nuts IdeasThe 15-Second Trick For Roof Nuts10 Easy Facts About Roof Nuts Shown

PVC roofing is not recommended for high slopes, as well as locations with hefty snowfall or freeze-thaw cycles. PVC roofing combines toughness with convenience of installation, making it a popular choice for numerous level roof applications.These systems, likewise referred to as accumulated roof covering, are composed of a number of layers of asphalt-impregnated roof covering felt and asphalt, developing a durable and leak-proof barrier versus the elements. The leading layer usually includes finely smashed rock granules, supplying a wear-resistant surface that can withstand the rigors of time. The organized application procedure of BUR assurances correct attachment of each layer, thus boosting the roof covering's general toughness and longevity.

Indicators on Roof Nuts You Should Know

Moreover, BUR is understood for its cost-effectiveness, using a competitive cost per year of expected life span contrasted to other commercial roof covering systems. With a lifespan varying from 15 to three decades, BUR offers a trustworthy and resilient roofing remedy for both household and industrial structures. Its capability to handle various climate condition and its cost-effectiveness make BUR an eye-catching choice for many homeowner.

Modified bitumen roof covering is manufactured into rolls with either smooth or granulated surface areas, giving various choices for different roof covering requirements. There are various kinds of customized asphalt roof covering, with common polymers such as atactic polypropylene (APP) and styrene butadiene styrene (SBS) utilized in the cap sheet.

The chilly adhesive approach entails using a particularly created glue to the substratum before laying down the customized asphalt sheets. There are also self-adhesive customized bitumen sheets that include a pre-applied adhesive layer, getting rid of the requirement for open flames throughout setup. Each technique has its advantages, but all require experienced experts to make certain optimal performance and durability

The smart Trick of Roof Nuts That Nobody is Discussing

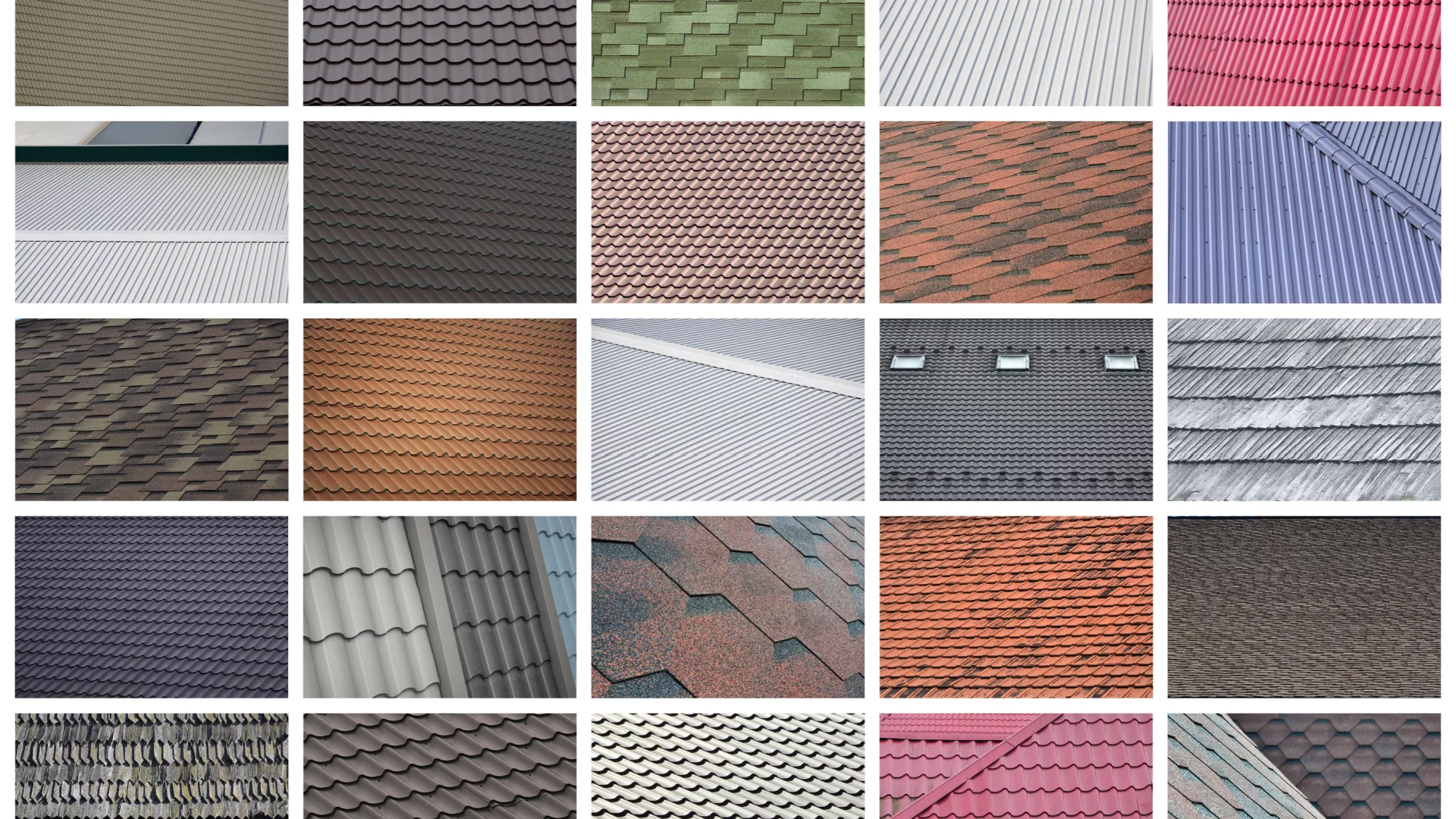

Steel roofs can dramatically improve the more tips here curb allure of your residential property, making them a popular option for both residential and industrial buildings. For level roofs, there are mostly two kinds of steel roofs: standing seam and screw-down panel systems. Standing joint metal roofings contain panels locked together at the joints, allowing for growth and tightening. Steel roofing offers numerous advantages, including durability and longevity. Metal level roofing can last approximately 35 years in ideal problems, making it a reliable long-term investment. Furthermore, steel roofs can rapidly drop snow and ice, stopping the buildup that can trigger damages. Nonetheless, among the significant downsides of steel roofing is its higher initial cost compared to other roofing materials.

Liquid roof covering has a reasonably straightforward application procedure that makes certain smooth, efficient protection. These systems can be put on a variety of surface areas, consisting of metal, BUR, and single-ply membrane layers. The complying with subsections will certainly discover the different sorts of fluid coatings and the application process in information. There are numerous types of liquid coatings made use of in roof, each offering distinct advantages: Silicone finishes master weather condition resistance and can stand up to ponding water without deteriorating.

A Biased View of Roof Nuts

Originally, the roofing surface area have to be extensively cleansed and fixed to remove any type of debris, dirt, or harmed locations that can prevent the finish's effectiveness. This preparation phase is essential as it sets the structure for a smooth and long lasting roof layer. As soon as the surface area is prepared, the liquid coating is generally applied making use of spray tools or rollers for even coverage.

The ordinary life expectancy of a flat roofing is about two decades, which affects the total worth stemmed from the first financial investment. Labor expenses are a substantial part of repair expenditures and can significantly influence the long-lasting worth of a flat roofing - https://disqus.com/by/ro0fnutsga/about/. Investing in a resilient and resilient roof material can save cash over time by reducing the frequency and price of repairs and upkeep